Introduction

In the last few years the ability to add "Keep-Alive" capacitors to sound decoders to improve performance on dirty rails or area with poor continuity like frogs and dead rail sections has become more common. Not only for sound decoders, even for regular decoders it can help make the overall performance of the locomotive a lot better. In my most recent decoder installations I've tried to include these capacitors. As I mostly use ESU decoders, I use the ESU Power Pack modules.

This video shows what a proper Keep-Alive system can do. It shows a Norwegian Di2 switcher with an ESU Power Pack. It is now a lot less susceptible to dirty track.

Some installation examples

The picture shows a sound installation in a Heljan Di3 locomotive. The ESU Power Pack is installed in the diesel tank.

Some other examples:

Some other examples:

- Heljan Di3.641 with ESU Power Pack

- Fleischmann DB 218 with TCS Keep-Alive

- Roco Di5 with ESU Power Pack

- NMJ Di2 with ESU Power Pack

- NMJ Superline Skd 220 with Train-O-Matic SPP

NMJ El13 (non-sound)

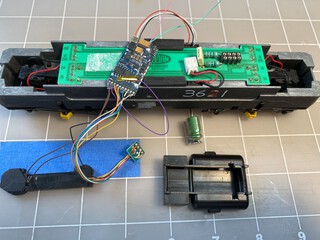

Non-sound locomotives can also get more reliable power pickup with keep-Alive modules installed. In this example we look at the Norwegian NSB El13. This model is made by NMJ and is a great runner. I've seen some occasional hick-ups while running at slower speed due to dirty tracks and wheels. Also the double slip switches in the Dombås train station can be a challenge.

To make space I removed the speaker, as I don't use sound in these electric locomotives. This gives the right space for the smaller ESU Power Pack. In the pictures you see it directly connected to an ESU Lokpilot 4.0.

To make space I removed the speaker, as I don't use sound in these electric locomotives. This gives the right space for the smaller ESU Power Pack. In the pictures you see it directly connected to an ESU Lokpilot 4.0.

Resources

Some references that I have used for keep-Alive/power pack installations.