Installation

In early 2003 I did a DCC conversion of a Roco El16 and I described all the steps on this page. Fast forward to 2016 and there are

better ways to do this conversion. See El16 with PLUX decoder for a new DCC conversion that I did in May 2016. This page is kept for reference.

Roco makes a very nice model of the Norwegian El16 class. The first run, in

the red and black 'ny design' colours, doesn't have the NEM interface so

it will take some effort to install a DCC decoder. The later run in the

old brown 'gammel design' colours does have the NEM interface so that makes

it a lot easier.

The Lenz LE1025 decoder is a great decoder that has one of the best

BEMF control on the market. Tony's Train Xchange does have a great

article

that compares this decoder with other BEMF decoders.

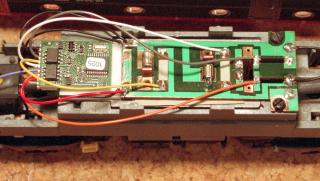

The following pictures shows a way of installing a LE1025 in the Roco

El16

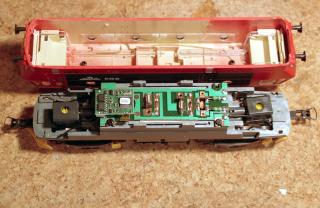

Remove the shell, by widening the body a little bit. The printed circuit

board is clearly visible. The Lenz decoder is shown in the location it will

be installed eventually. Currently this space is occupied by a switch that

allows to change the power pickup from track to overhead wire.

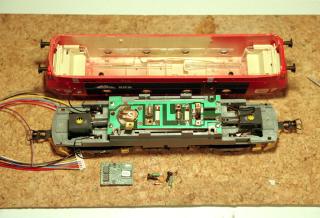

The resistors, capacitor and diodes need to be removed. This picture shows

the printed circuit board after the removal of these components. Compare

with the previous picture for their location. The capacitor sits

underneath the board between the copper strips that attach to the motor.

The printed circuit board is removed and with a small saw the left part

that holds the switch is removed.

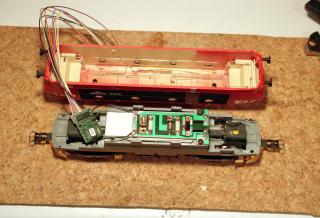

The switch is gone and in its place sits a piece of white double sided

tape. The wires from the bogies are attached again. This requires scrapping

off a little bit of isolation of the circuit board.

The decoder is put into place and the red and black decoder wires are

soldered to the track pickup locations on the circuit board.

The orange and grey wires are soldered to the motor pickup locations, where

the capacitor used to sit.

After this is done put the locomotive on the track and select number '3'.

If everything is alright the locomotive should run. Please note the

direction, because we need this for connecting the function wires.

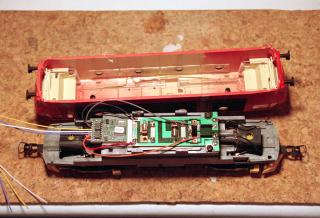

If the locomotive doesn't run check the wiring again and compare it with

the next picture which has a more closeup view of the decoder, printed

circuit board and the wires.

The white wire is for the front lights and connect it to the light that is

'front'. The yellow wire goes to the rear. In this example the blue common

wire is not used because the lights are connected to one of the pickup

wires on the print circuit board. In this configuarion the lights will get

half the voltage they used to get. If you prefer to use the blue wire then

you have to isolate both lights from the pickup wire on the printed circuit

board.

A piece of electrical tape is used to secure the wires and the decoder and

the shell/body can be put back on the frame. Make sure that 'cab 1' is

sitting in the front location.

The last step is to the program track to program a new address. I use four

digit addressing and normally use the last four digits from a Norwegian

locomotive number for the address. So in this case the El16.2212 will get

address 2212.